How to design a negative pressure suction pneumatic conveying Roots blower system

The negative pressure suction pneumatic conveying Roots blower system is a reliable material conveying method widely used in industries such as chemical, grain, pharmaceutical, and building materials. The following is a detailed explanation of the system design and principles:

1、 System Design

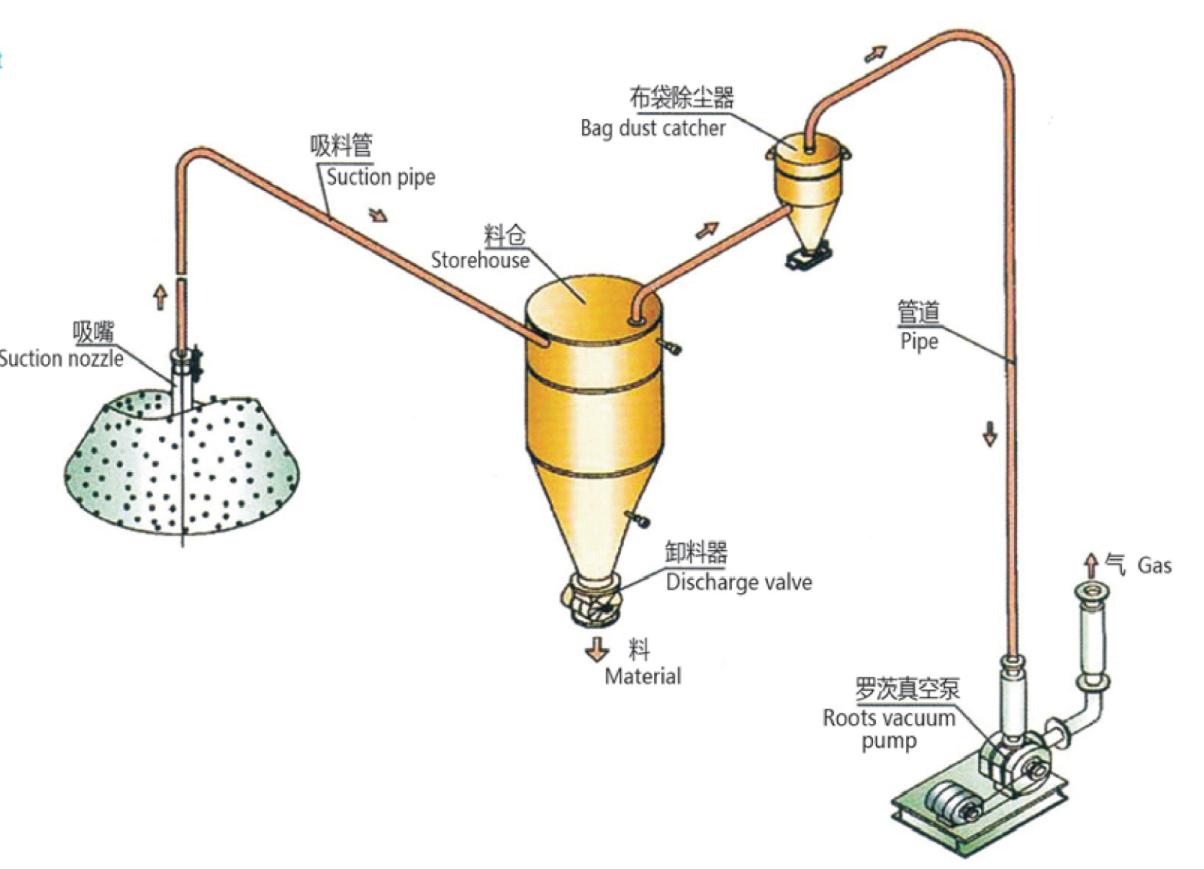

The negative pressure suction pneumatic conveying Roots blower system mainly consists of Roots blower, storage bin, conveying pipeline, separation device (such as filter, cyclone separator, etc.), and control system.

1. Roots blower: As the core equipment of the system, the Roots blower generates negative pressure at the inlet through its rotation, thereby sucking in materials. The selection should be comprehensively considered based on factors such as material properties, conveying distance, and conveying volume.

2. Storage bin: Used for storing materials to be transported, its design needs to consider factors such as material fluidity, storage capacity, and unloading methods.

3. Conveyor pipeline: Connect the Roots blower, storage bin, and separation device to ensure smooth transportation of materials in the pipeline. The design of pipelines needs to consider factors such as material wear, conveying speed, and pipeline material.

4. Separation device: used to separate materials from airflow, ensuring that the materials are collected into designated containers, while the clean airflow is discharged through the exhaust port of the fan. Common separation devices include filters, cyclone separators, etc.

5. Control system: used to control the start, stop, speed regulation, etc. of Roots blower, as well as monitor the operating status and fault alarms of the system.

2、 Working principle

The working principle of the negative pressure suction pneumatic conveying Roots blower system is mainly based on the volumetric characteristics of the Roots blower and the negative pressure suction principle.

1. Working principle of Roots blower: Roots blower is a positive displacement fan that mainly relies on two blade rotors (usually three bladed impellers) moving relative to each other in the cylinder to compress and transport gas. When the motor drives one of the impellers to rotate, the other impeller will rotate synchronously at the same speed and in the opposite direction through the action of the synchronous gear. Due to the gaps between impellers, impellers and casings, and impellers and wall panels, a vacuum state is formed at the inlet during the rotation of the impeller, and air is drawn into the inlet chamber under atmospheric pressure. As the impeller continues to rotate, two of the blades of each impeller form a sealed chamber with the wall panel and casing, and the air in the intake chamber is continuously carried to the exhaust chamber by the sealed chamber formed by these two blades. Also, because the impellers in the exhaust chamber are interlocked, the air between the two blades is squeezed out. Through continuous inhalation and compression, air is transported from the inlet to the outlet on site, completing the entire gas transportation process.

2. Principle of negative pressure suction: The Roots blower generates negative pressure at the inlet of the blower through its rotation. This negative pressure environment causes the materials in the storage bin or container to be subjected to the action of external atmospheric pressure, thereby being sucked into the intake duct of the fan. The inhaled material is propelled forward along the pipeline by the Roots blower. Roots blower can provide stable and continuous airflow, ensuring smooth transportation of materials in pipelines. During the transportation process, materials usually need to be separated from the airflow through separation devices such as filters, cyclone separators, etc. The separated materials are collected in designated containers, while the clean airflow is discharged through the exhaust port of the fan.

3、 System features

1. Sex: Roots blowers can provide stable and continuous airflow, ensuring smooth transportation of materials in pipelines and improving transportation efficiency.

2. Flexibility: Roots blowers are usually equipped with regulating devices such as frequency converters, throttle valves, etc., which can adjust the fan speed and air volume according to actual needs, thereby achieving control over material conveying speed and flow rate.

3. Wide applicability: Roots blowers are suitable for conveying various materials such as powders, granules, and fibers, and can be widely used in industries such as chemical, grain, pharmaceutical, and building materials.

4. Easy maintenance: The Roots blower has a simple structure and rarely malfunctions during operation. In addition, its durable material selection allows the blower to maintain good performance even during long-term continuous operation.

In summary, the negative pressure suction pneumatic conveying Roots blower system has been widely used in multiple industrial fields due to its flexibility, strong applicability, and easy maintenance.