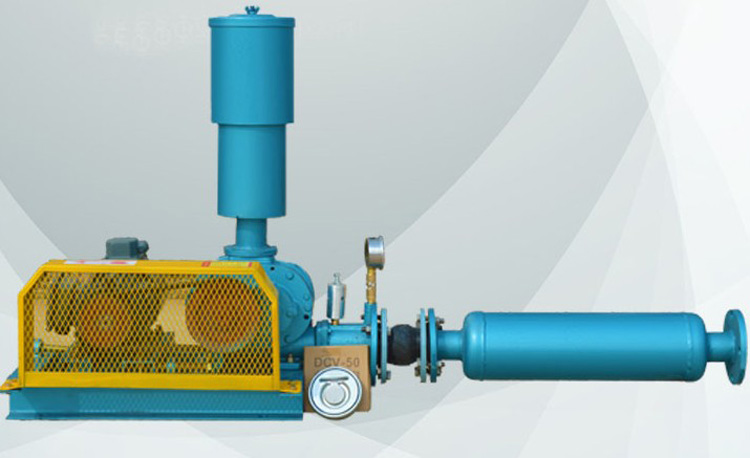

Working principle and application of Roots blower on papermaking machinery equipment

Roots blowers play a crucial role in papermaking machinery and equipment. The following is a detailed introduction to its working principle and application:

1、 Working principle

Roots blower is a type of rotary positive pressure blower, whose working principle is mainly based on two synchronously rotating impellers. These two impellers move relative to each other inside the cylinder, compressing and transporting gas through the small gap between them. Specifically:

1. Inhalation process: When two impellers rotate towards each other, a vacuum state is formed at the inlet due to the gaps between impellers, impellers and casings, and impellers and wall panels. Under the action of atmospheric pressure, air is drawn into the intake chamber.

2. Compression process: As the impeller continues to rotate, two of the blades of each impeller form a sealed chamber with the wall panel and casing. The air in the intake chamber is continuously carried to the exhaust chamber within this sealed chamber.

3. Exhaust process: Due to the meshing of the impellers in the exhaust chamber, they squeeze out the air between the two blades. In this way, air is transported from the inlet to the outlet on site.

2、 Application

In papermaking machinery equipment, Roots blowers are mainly used in the following areas:

1. Ventilation of papermaking machinery:

Roots blower can provide necessary ventilation for paper machinery, helping equipment maintain normal operation in high temperature environments.

Through reasonable ventilation design, the temperature of equipment can be reduced and the service life of equipment can be extended.

2. Paper adsorption:

In the paper production process, Roots blowers can use negative pressure to adsorb paper, making it smoother and more stable on the production line.

This negative pressure adsorption effect helps improve the production quality and efficiency of paper.

3. Waste gas treatment:

The production process of the paper industry generates a large amount of exhaust gas, which, if not treated and directly discharged into the atmosphere, can cause serious pollution to the environment.

Roots blower can collect these exhaust gases and treat them through exhaust gas treatment equipment to meet emission standards.

3、 Advantages

The use of Roots blowers in papermaking machinery equipment has the following advantages:

1. Simple structure: The structure of Roots blower is relatively simple, easy to manufacture and maintain.

2. Low noise: The operating noise of Roots blower is relatively small and will not cause too much interference to the working environment.

3. Energy saving: Roots blowers have high efficiency and can effectively convert electrical energy into mechanical energy, saving energy.

4. Strong durability: The body and impeller of the Roots blower are made of high-strength materials, which have strong durability and corrosion resistance.

In summary, Roots blowers play a crucial role in papermaking machinery and equipment. Its working principle and wide range of applications make it one of the indispensable equipment in the paper industry.