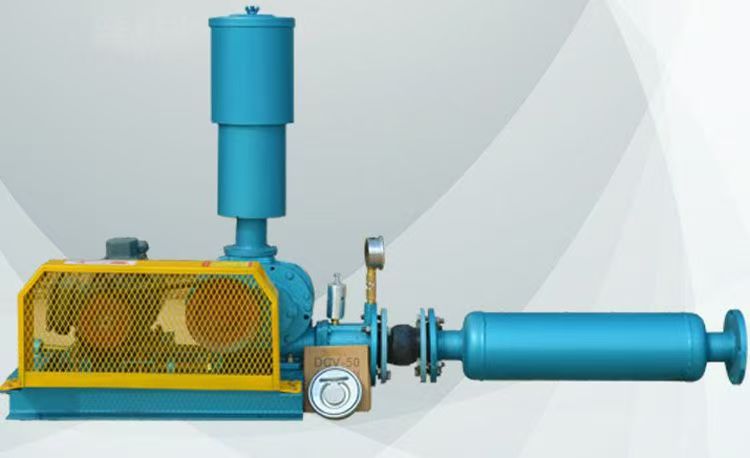

Roots negative pressure suction fan

Roots negative pressure suction fan, also known as negative pressure Roots blower, is a commonly used air source equipment with a wide range of applications in various industrial fields. The following is a detailed introduction to Roots negative pressure suction fan:

1、 Working principle

The working principle of the negative pressure Roots blower is mainly based on the Roots principle, which achieves gas compression through a dual blade impeller structure. Specifically, there are two interlocked impellers inside the fan, which rotate around an axis to suck gas in from the inlet, compress it in the compression chamber, and then discharge it from the outlet. When the impeller rotates, the gas located between the impellers is compressed, forming negative pressure, thereby sucking in new gas. This process is driven by an electric motor to rotate the impeller and achieve compression, while the fan housing and inlet/outlet are isolated from the compressed gas.

2、 Application Fields

Roots negative pressure suction fans are widely used in industries such as grain processing, feed processing, chemical, building materials, metallurgy, and environmental protection. In grain processing, it can be used for processes such as grain storage, ventilation, and transportation; In the environmental protection industry, it can be used for aeration, stirring and other processes in sewage treatment systems. In addition, Roots blowers can also be used in mining ventilation systems, cement conveying systems, paper production lines, and other fields.

3、 Performance characteristics

1. Pressure and air volume stability: The pressure change of Roots blower has little effect on the air volume, and its speed is proportional to the air volume, so it basically belongs to constant volume blower.

2. No pulsation phenomenon: During the suction and exhaust process, the Roots blower has no pulsation phenomenon and does not require a buffer gas tank.

3. Small footprint: Roots blower has a small footprint, making it easy to arrange and install.

4. Allow dusty airflow: There should be a gap of 0.2-0.5mm between the rotor and the transfer, and between the rotor and the housing, without friction, and the airflow is allowed to contain dust.

5. Reliable operation: Compared with hydraulic jet pumps and water ring vacuum pumps, Roots blowers do not have the problem of "exhaust with water", and are reliable in operation and easy to maintain.

4、 Types and choices

There are various types of Roots blowers, such as three blade Roots blowers, two blade Roots blowers, and two-stage series Roots blowers. Among them, the three blade Roots blower is a commonly used type with relatively small air volume; When the air volume is high, a two blade Roots fan is generally used; If both high air volume and high pressure requirements need to be met, a two-stage series Roots blower can be selected. When choosing a Roots blower, comprehensive consideration should be given to specific usage scenarios, air volume requirements, pressure requirements, and other factors.

5、 Maintenance and upkeep

In order to ensure the normal operation and prolong the service life of Roots negative pressure suction fans, regular maintenance and upkeep are necessary. This includes checking whether the fasteners of the fan are loose, whether the bearings are well lubricated, and whether the seals are worn. At the same time, it is necessary to regularly clean the dust and debris inside the fan to maintain its cleanliness and smoothness.

In summary, Roots negative pressure suction fans play an important role in multiple industrial fields due to their unique working principle and superior performance characteristics. During use, it is important to choose the appropriate type and perform regular maintenance and upkeep to ensure its normal operation and extend its lifespan.