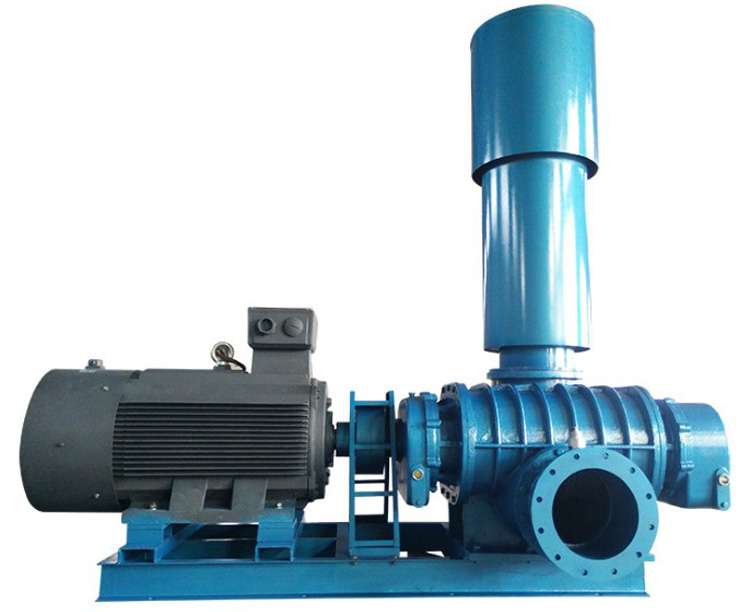

The Roots blower used for coal washing plays a crucial role in the coal industry, and its working principle and selection principles are essential for ensuring the normal operation of the coal washing machine and achieving coal washing.

1、 Working principle

The working principle of the Roots blower used for coal washing is based on the principle of volumetric compression. The fan is mainly composed of a shell, impeller (rotor), main shaft, inlet and outlet, and sealing device. When the driving device drives the impeller to rotate at high speed, the two gear shaped rotors mesh with each other in two different chambers inside the housing but do not directly contact each other. As the rotor rotates, they move along the inner surface of the housing and the gaps between each other, thereby changing the volume of the corresponding chamber.

Specifically, the working principle includes the following steps:

1. Air intake: As the rotor rotates, a pair of rotor blades inside the casing gradually separate, forming a gradually expanding air intake chamber. External air (mainly impurities such as coal powder in coal washing applications) enters the chamber through the air inlet under atmospheric pressure.

2. Closure and compression: The rotor continues to rotate, and the intake chamber gradually shrinks until it is closed. At this point, the volume of air (impurities such as coal powder) enclosed between the two rotor blades is forcibly reduced, resulting in the compression of gas (impurities such as coal powder).

3. Exhaust: As the rotor continues to rotate, the compressed gas (impurities such as coal powder) is pushed towards the exhaust side. When the rotor blades are opened again, high-pressure gas (such as coal powder and other impurities) is quickly discharged to the exhaust port, achieving the separation and cleaning effect of coal powder and other impurities.

2、 Selection principle

Choosing a suitable Roots blower is one of the key factors in ensuring the normal operation of the coal washing machine. When selecting, the following factors should be considered:

1. Airflow: The size of the airflow is determined based on the structure, specifications, and power parameters of the coal washing machine. The reserve capacity should generally be considered when determining the air volume to ensure the stable operation of the fan and the effectiveness of coal washing.

2. Wind pressure: The wind pressure requirement of the coal washing machine for the Roots blower is generally between 80~150kPa. The specific selection should be based on the coal quality, moisture content, and washing effect of the coal washing machine. The selection of wind pressure should ensure that the fan can provide sufficient pressure to push impurities such as coal powder through the coal washing machine.

3. Efficiency: The higher the efficiency of the Roots blower, the better. Efficiency can be improved through measures such as optimizing speed, impeller diameter, gear ratio, and impeller type to achieve energy conservation, emission reduction, and cost reduction.

4. Noise: The noise of Roots blower is one of the key factors to consider when selecting. The appropriate noise level should be selected based on the operating environment and conditions of the coal washing machine. Usually, fans with high efficiency and low noise are the preferred choice.

5. Materials and Durability: Due to the large amount of particulate matter and chemicals generated during coal washing, Roots blowers should use high-quality materials and designs to ensure their durability and reliability. For example, using alloy steel materials to manufacture rotors, using high-precision lubricants, etc.

In addition, when selecting, factors such as the maintenance cost, service life, and manufacturer's after-sales service of the fan should also be considered. Suggest consulting, suggesting, and planning with technical personnel to ensure the selection of a Roots blower that suits your needs.