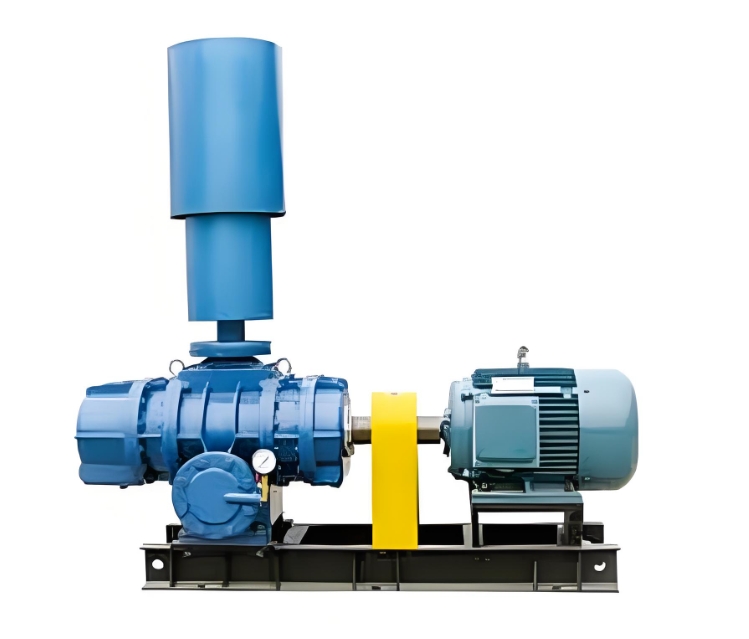

The following is an overview of the Roots blower manual, which includes information about the main features, operating conditions, installation and commissioning, maintenance and upkeep of the Roots blower:

1、 Main features

Roots blower is a type of positive displacement blower with the following characteristics:

The air volume transported is proportional to the rotational speed, and the flow rate and shaft power can be changed by adjusting the rotational speed.

There is always a small gap between the impeller end face and the front and rear end covers of the fan, as well as between the fan impellers, and no lubricating oil is needed in the fan cavity.

Energy saving, high precision, long lifespan, compact structure, small size, light weight, and easy to use.

The product has a wide range of applications, covering various fields such as petrochemicals, building materials, electricity, smelting, fertilizers, mining, ports, textiles, food, papermaking, aquaculture, sewage treatment, and industry.

2、 Usage conditions

To ensure the normal operation of the Roots blower, the following conditions must be met:

1. The temperature of the imported gas should not exceed 40 ℃. If it exceeds this limit, cooling measures should be taken.

2. The solid particle impurity content in the inhalation medium shall not exceed 100mg/m3, and the particle size shall not exceed 1/2 of the working gap.

3. The fan should operate within the specified pressure range and not exceed the pressure specified on the nameplate. It should be started or stopped under no load, otherwise it may damage the motor and fan.

4. The place where the blower is installed should be in a bright and dust-free building environment. Necessary rainproof measures should be taken when setting it outdoors, and special attention should be paid to the protection of the motor and V-belt.

3、 Installation and piping

The installation and piping of Roots blower should follow the following steps and precautions:

1. The foundation of the fan needs to use concrete foundation, and fully consider the weight of the blower and the pressure resistance of the foundation, so that the foundation has sufficient load-bearing area.

2. When installing the whole machine, place the blower on the foundation and insert a shim between the base and the foundation surface to evenly support and level the base.

3. When installing pipelines, it is not allowed to use 90 ° right angle bends, and there should not be too many bends to avoid causing system resistance. Various types of debris such as rust, foreign objects, dust, etc. should enter and exit various pipelines.

4. Elastic joints should be installed on the outlet side, and support devices should be installed for other pipelines to prevent the blower from bearing additional loads. A pressure gauge must be installed on the outlet side of the blower, and the range of the pressure gauge should meet the requirements of the usage range.

5. Install valves (usually installed on the air outlet connection of the blower) and one-way valves to prevent system overload and gas backflow, which may damage the blower. The one-way valve must be installed on a horizontal pipeline, with the valve disc support shaft directly above and the valve disc opening direction consistent with the wind direction.

4、 Trial operation and working operation of the fan

1. Preparation for trial operation:

Check whether all fasteners, intake and exhaust pipes, valves are firmly and reliably connected, and whether the cooling water pipeline can supply water normally.

Fill the fuel tank with oil slightly above the red dot on the oil level window. The lubricating oil grade is N220 medium load industrial gear oil for ordinary fans and N320 medium load industrial gear oil for high-pressure fans.

Rotate the steering wheel and turn the fan according to the instructions on the blower belt cover, and check for any abnormal phenomena.

Open the valves of the inlet and outlet pipelines. The fan must be started in a no-load state.

2. Trial operation:

For newly installed, overhauled, or unused blowers, a trial run must be conducted.

Turn on the power switch and confirm the direction of motor rotation (indicated on the cover). For fans that require cooling, the cooling water valve should be opened first.

After starting, run the machine for 30 minutes and check for any abnormal vibration or heating. If any abnormalities occur, stop the machine and investigate the cause.

Run without load without any abnormal conditions, gradually close the vent valve to reach the rated pressure, and pay attention to observing whether the fan temperature, vibration, current, and voltage are normal.

3. Work operation and precautions:

After confirming the normal operation during the trial run, the fan can be put into operation.

During operation, it is necessary to regularly check the oil temperature, ammeter, and bearing temperature, usually every 15 minutes.

The flow rate cannot be adjusted by opening or closing the valve. The fan is damaged during overload operation, especially when the motor current value is lower than the rated value on the nameplate, otherwise the motor life will be reduced or burned.

When stopping, it is necessary to first relieve pressure and load, then stop and turn off the cooling water. The fan must be shut down in a no-load state.

5、 Maintenance and upkeep

To ensure the operation and service life of Roots blowers, regular maintenance and upkeep should be carried out:

1. When abnormal vibrations and overheating occur in the casing, wall panels, fuel tank, etc. during operation, the machine should be stopped immediately for inspection.

2. Regularly clean the fan room, keep the environment clean and well ventilated, and prevent impurities such as dust and moisture from entering the inside of the fan.

3. Regularly clean the casing, inlet, and outlet of the Roots blower, as dust accumulation can affect heat dissipation and ventilation efficiency.

4. Clean or replace the filter to prevent dust and impurities from entering the interior of the blower, ensuring the normal operation of the machine.

5. According to the manufacturer's recommendations, regularly lubricate the bearings, gears, and other components of the Roots blower to ensure smooth machine operation.

6. Regularly check the fastening condition of various parts of the Roots blower, including bolts, nuts, locating pins, etc., for faults caused by looseness.

7. Regularly inspect the performance and operational status of Roots blowers, including measuring and calibrating parameters such as pressure, flow rate, temperature, and vibration.

6、 Fault analysis and troubleshooting

Roots blowers may encounter various faults during use, such as impeller to impeller friction, impeller to wall friction, high temperature, insufficient flow, oil leakage or oil leakage into the casing, abnormal vibration and noise, motor overload, etc. For these faults, corresponding analysis and troubleshooting work should be carried out, such as dirt, adjusting gear clearance, replacing bearings, readjusting clearance, reducing oil level or oil entrapment, blocking objects, increasing speed, replacing seals, clearing ventilation openings, replacing bearings or bearing seats, reinstalling gears, cleaning blowers, checking back pressure, adjusting clearance, reducing pressure, obstacles, checking belt tension, etc.

In short, Roots blower is an energy-saving and widely used positive displacement fan. During use, the usage conditions should be strictly followed, installation and piping should be carried out correctly, trial operation and working operation should be carried out according to the prescribed steps, and regular maintenance and upkeep should be carried out to ensure the operation and service life of the fan.