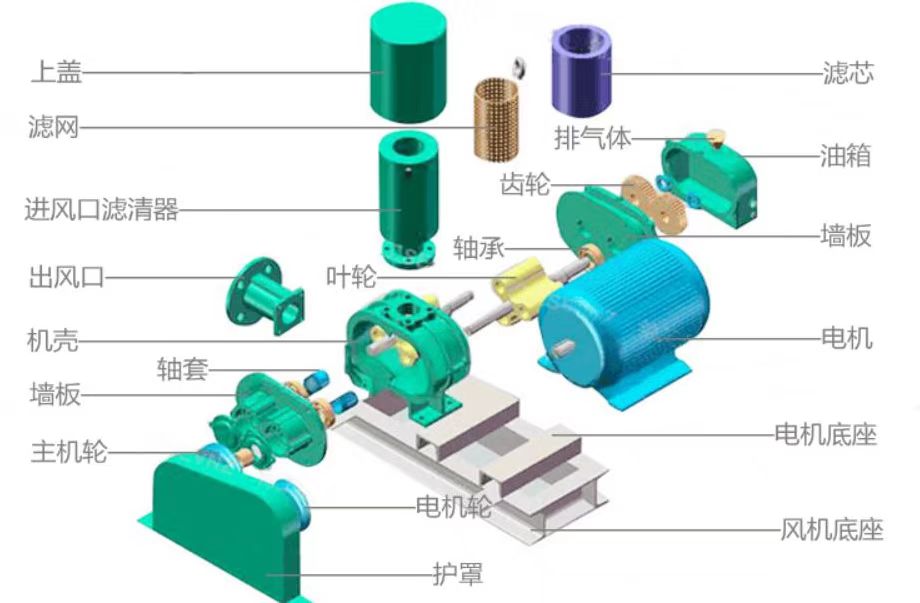

Internal structure of Roots blower

Roots blower is a volumetric fan with a relatively complex internal structure but exquisite design. The following is a detailed analysis of the internal structure of Roots blower:

1、 Main components

1. Shell: The shell is the main part of the Roots blower, mainly used for support and fixation. It is usually made of high-quality steel plates or cast iron to ensure its strength and durability. There are two parallel rotors inside the casing, with small gaps between them and between the rotors and the casing.

2. Wall panel: The wall panel is used to connect the casing with the rotor and support the rotation of the rotor. Wall panels are usually made of thick steel plates to ensure that they can withstand the rotational force and pressure of the rotor. The wall panel also serves as an end face seal to prevent gas leakage.

3. Impeller (rotor): The impeller is the core component of a Roots blower, and its shape is usually involute or similar, such as an "8" shape. The design of a three bladed impeller has more advantages than a two bladed impeller, such as smaller exhaust pulsation, lower noise, and smoother operation. During the rotation of the impeller, the blowing effect is achieved by continuously squeezing and conveying gas.

4. Gears: Roots blowers typically use synchronous gears to ensure synchronous rotation of the two rotors. Gears are composed of gears and wheel rims, making it easy to adjust the clearance of the impeller. The accuracy and wear resistance of gears have a significant impact on the performance and lifespan of fans.

5. Bearings: Bearings are used to support the rotation of rotors and reduce friction and wear. Roots blowers typically use high-quality bearings to ensure they can withstand high-speed rotation and heavy loads.

2、 Internal structural details

1. Gap adjustment: There is a small gap between the rotors and between the rotors and the casing of the Roots blower. The adjustment of these gaps has a significant impact on the performance and lifespan of the fan. Usually, gap adjustment is achieved by adjusting the position of gears and tightening bolts.

2. Lubrication system: The gears and bearings of the Roots blower require good lubrication to ensure its normal operation. Lubrication systems typically use immersion or splash lubrication methods to deliver lubricating oil to gears and bearings for lubrication.

3. Sealing device: The sealing device of Roots blower is used to prevent gas leakage and maintain cleanliness inside the fan. Sealing devices are usually composed of components such as sealing rings, gaskets, and sealants.

3、 Working principle

The working principle of Roots blower is based on the synchronous rotation of two impellers. When two impellers rotate relative to each other inside the casing, the gas between them is constantly squeezed and transported. Due to the adjustment of the shape and clearance of the impeller, gas is continuously carried to the exhaust port during the rotation of the impeller, thereby achieving the blowing effect.

In summary, the internal structure of Roots blower includes components such as casing, wall panels, impeller (rotor), gears, bearings, etc. These components work together to achieve the blowing function of the fan. In the design and manufacturing process, it is necessary to strictly control the quality and accuracy of each component to ensure the performance and lifespan of the fan.