Introduction to Direct Connect Roots Blowers

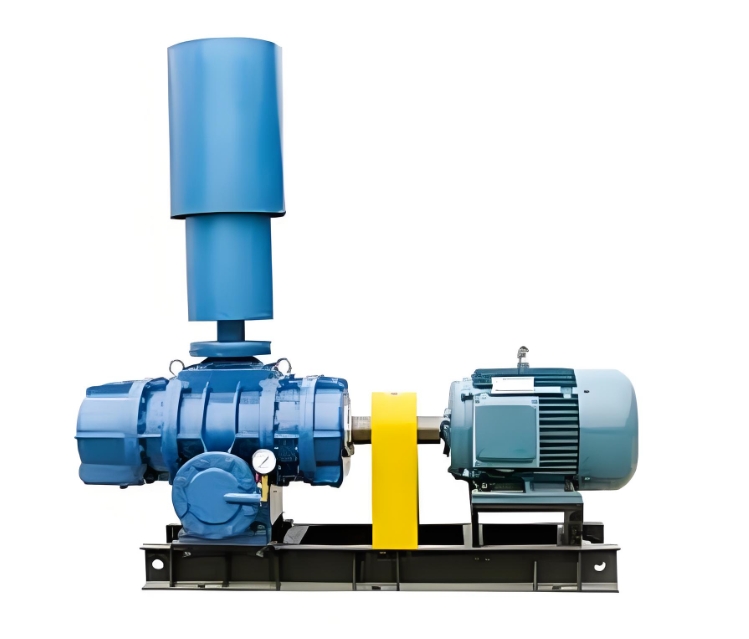

Directly connected Roots blower, as an important mechanical equipment, plays a crucial role in multiple industrial fields. The following is a detailed introduction to the direct connection Roots blower:

1、 Working principle

The working principle of a direct connected Roots blower is similar to other types of Roots blowers, which use two bladed rotors (usually three bladed) to compress and transport gas through relative motion within a cylinder. After the motor starts, the spindle begins to rotate, and the rotor sucks in gas and compresses it in the cylinder, then exhausts the gas through the exhaust port. This working principle enables the direct connected Roots blower to have high exhaust efficiency and pressure stability.

2、 Structural characteristics

The direct connected Roots blower is mainly composed of a casing, wall panels, impellers, inlet and outlet mufflers, and other parts. The specific functions of each part are as follows:

1. Chassis: It mainly plays a supporting and fixing role, providing a stable operating environment for the internal rotor.

2. Wall panel: connects the casing and impeller, supports the rotation of the impeller, and also serves as an end face seal to prevent gas leakage.

3. Impeller: It is the rotating part of a fan, divided into two types: two blades and three blades. Three bladed impellers are gradually replacing two bladed impellers due to their advantages of smaller air flow pulsation, lower noise, and smoother operation.

4. Muffler: Used to reduce the noise generated by airflow pulsation at the inlet and outlet of the fan, and improve the comfort of equipment operation.

3、 Performance advantages

1. Stability: Directly connected Roots blowers have high exhaust efficiency and pressure stability, which can meet the exhaust needs of various industrial fields.

2. Easy maintenance: Due to the lack of transmission components such as belts, the direct connected Roots blower is relatively easy to maintain and reduces operating costs.

3. Strong adaptability: Directly connected Roots blower is suitable for harsh environments such as high temperature and high pressure, and can meet the needs of different working conditions.

4、 Application Fields

Directly connected Roots blowers are widely used in multiple industrial fields, including but not limited to:

1. Steel industry: In the process of steel smelting, direct connection Roots blowers are used to provide high-pressure gas to meet production needs.

2. In the field of environmental protection, direct connection Roots blowers play an important role in sewage treatment, exhaust gas treatment, and other aspects, contributing to the environmental protection cause.

3. Food processing: In the food processing industry, direct connected Roots blowers are used for conveying materials, ventilation, etc., to ensure a clean and hygienic production environment.

4. Aquaculture: In aquaculture, direct connected Roots blowers are used to provide sufficient oxygen, promote respiration and growth of aquatic organisms.

5、 Selection suggestions

When choosing a direct connected Roots blower, the following factors need to be considered:

1. Air volume requirement: Select the appropriate fan model and specifications based on the air volume requirements of the usage scenario.

2. Pressure requirements: Choose the appropriate fan type and configuration based on the required pressure.

3. Work environment: Consider the working environment of the fan, such as temperature, humidity, corrosiveness, and other factors, and choose suitable materials and protective measures.

4. Energy consumption and cost: Taking into account the energy consumption and operating costs of the fan, choose an economically reasonable solution.

6、 Maintenance and upkeep

To ensure the long-term stable operation of the direct connected Roots blower, regular maintenance and upkeep are required. Specific measures include:

1. Regular cleaning: Regularly clean the dust and dirt inside the fan to keep the equipment clean.

2. Check lubrication: Regularly check the oil level and quality of lubricating oil, and add or replace lubricating oil in a timely manner.

3. Tighten bolts: Regularly inspect and tighten the bolts of various components of the fan to prevent loosening and detachment.

4. Monitoring operation: Regularly monitor the operating status of the fan, such as vibration, noise, temperature and other indicators, and promptly detect and handle abnormal situations.

In summary, direct connected Roots blowers have been widely used in various industrial fields due to their advantages of stability, easy maintenance, and strong adaptability. In the process of selection and use, it is necessary to make reasonable selection and regular maintenance according to actual needs to ensure the long-term stable operation of the equipment.