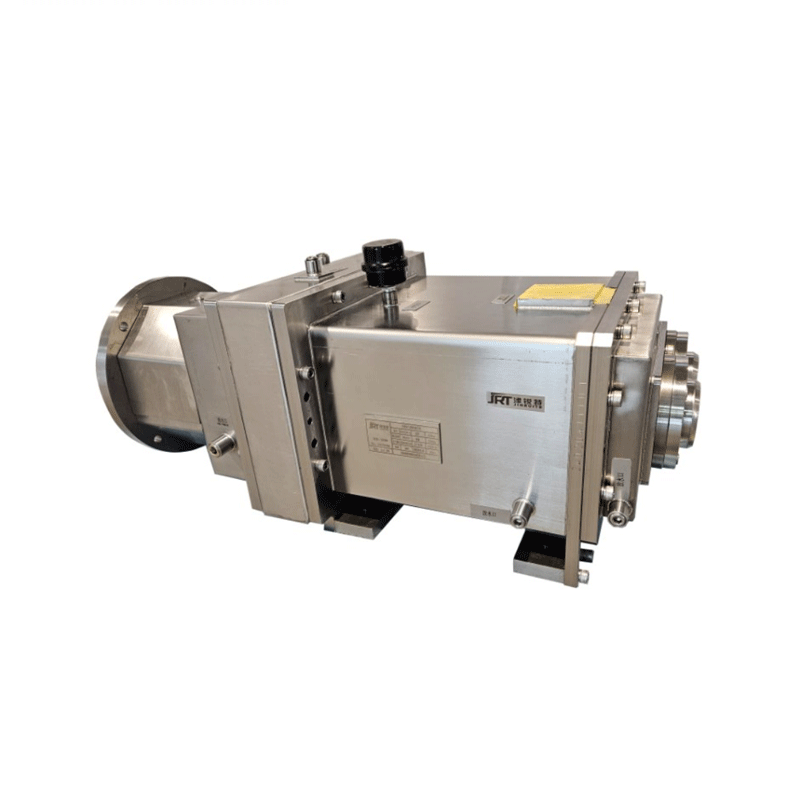

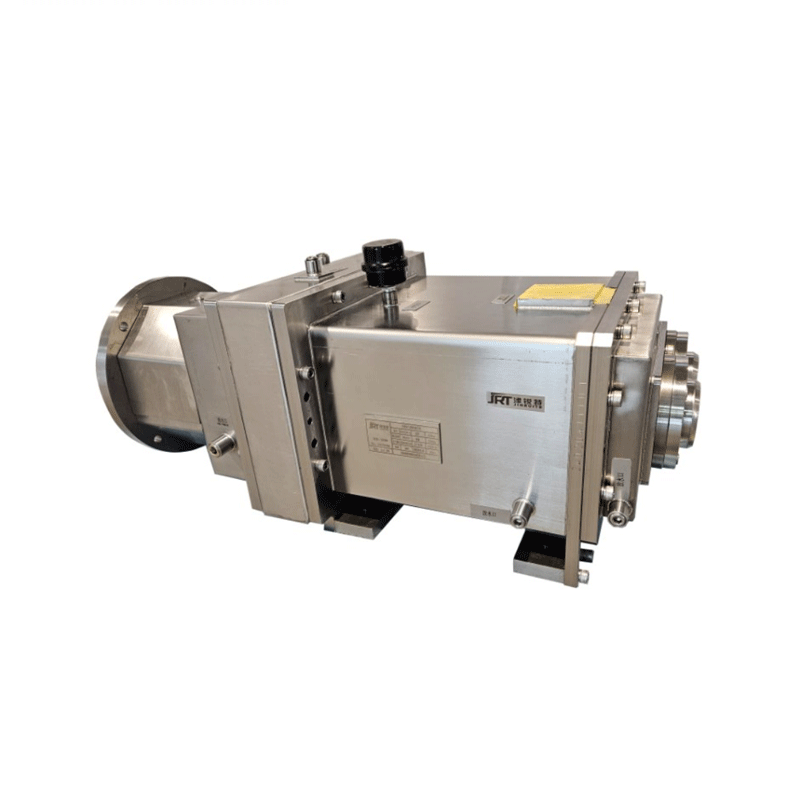

Stainless steel screw vacuum pump is a type of dry positive displacement vacuum pump, which rotates in the pump chamber through a pair of precision meshing screw rotors to achieve gas suction, compression, and discharge. The following is a detailed analysis of its working principle:

---

**1、 Core working principle**

1. * * Rotor motion**

-* * Master slave rotor * *: A pair of stainless steel (usually 304/316L material) spiral screws, designed with asymmetric double or multiple heads, synchronously rotating in the opposite direction through high-precision gears.

-Non contact meshing: Maintain a gap of 0.1-0.3mm between rotors to avoid metal friction (no lubrication required).

2. * * Working process**

-* * Inhalation stage * *: Gas enters the closed chamber formed by the rotor and pump casing from the intake port (Figure ①).

-Compression stage: The rotation of the rotor gradually reduces the volume of the chamber, and the gas is pushed axially and compressed (Figure ② → ③).

-Exhaust stage: Compressed gas is discharged from the exhaust port (Figure ④).

```plaintext

[Schematic diagram of work cycle]

① Inhalation → ② Closure → ③ Compression → ④ Exhaust

```

3. * * Dry operation**

-No oil/water involvement throughout the process, suitable for clean working conditions such as medicine and food.

-Relying on rotor clearance and surface coating (such as PTFE) to achieve sealing.

---

**2、 Key structural components**

|* * Components * * | * * Functions * * | * Advantages of Stainless Steel * *|

|-------------------|-------------------------------------------------------------------------|----------------------------------|

|* * Screw rotor * * | Gas compression core, requiring dynamic balance correction | Corrosion and high temperature resistance (up to 300 ℃)|

|* * Pump casing * * | Forming a closed chamber with cooling jacket (water-cooled/air-cooled) | Resistant to chemical media erosion|

|* * Synchronous gear * * | Ensure rotor meshing (ISO grade 4 accuracy) | Surface chrome plated for rust prevention|

|* * Bearing assembly * * | Bearing for axial/radial forces (commonly used angular contact ball bearings) | 316L material suitable for harsh environments|

---

**3、 Performance characteristics**

1. Vacuum range**

-Ultimate vacuum: 0.1~10 Pa (can reach 102 Pa with Roots pump).

-* * Work pressure * *: atmospheric pressure~0.1 Pa (single-stage), multi-stage series expandable.

2. * * Traffic characteristics**

-Flow range: 5-2000 m3/h (positively correlated with rotor diameter and speed).

-Constant flow output (volumetric characteristic).

3. * * Advantage Comparison**

-* * vs rotary vane pump * *: No oil pollution, maintenance cost is 50% lower.

-* * vs Roots pump * *: Single stage compression ratio (up to 10:1), no need for a front stage pump.

---

**4、 Typical application scenarios**

|* * Industry * * | * * Purpose * * | * * Special Requirements * *|

|------------------|----------------------------------|----------------------------------|

|* * Pharmaceutical * * | Freeze drying machine, sterile packaging | FDA certification required (material 316L+electrolytic polishing)|

|Chemical industry * * | Solvent recovery, vacuum distillation | Explosion proof design (Ex d Ⅱ BT4)|

|* * Electronics * * | Semiconductor coating, LED packaging | Extreme vacuum ≤ 1 Pa, vibration<1.5 μ m|

|* * Food * * | Vacuum packaging, dehydration drying | Compliant with NSF lubricant standards|

---

**5、 Workflow Example (Taking Pharmaceutical Freeze Drying as an Example)**

1. * * Evacuation stage * *: Within 30 minutes, pump from atmospheric pressure to 10 Pa (remove air and moisture).

2. * * Maintenance stage * *: Stabilize at 1-5 Pa for 48 hours (sublimation drying).

3. * * Breaking stage * *: Inject sterile nitrogen gas to restore normal pressure.

---

**6、 Maintenance points**

1. * * Daily inspection**

-Rotor clearance (measured monthly, adjusted for wear>0.05mm).

-Gearbox oil level (replace synthetic oil every 2000 hours).

2. * * Deep maintenance**

-Inspect the rotor coating annually (if the peeling area is greater than 5, it needs to be repainted).

-The bearing life is usually 20000 hours (replaced when the vibration value is greater than 4.5mm/s).

---

**7、 Troubleshooting Guide**

|* * Fault phenomenon * * | * * Possible cause * * | * * Solution * *|

|------------------|------------------------------|----------------------------------|

|Vacuum degree decrease | rotor coating wear/system leakage | helium leak detection+coating repair|

|Abnormal vibration | Bearing damage/rotor dynamic balance failure | Replace bearings+re calibrate dynamic balance|

|Overheating (>90 ℃) | Blockage of cooling system/high compression ratio | Clean cooling channel+check exhaust back pressure|

---

**Tip: When selecting, attention should be paid to the gas composition (corrosive gases require special rotors) and particulate matter content (>5 μ m requires a pre filter). Although stainless steel screw pumps are expensive (30-50% more expensive than cast iron), their lifespan can reach more than 10 years.