The maintenance of a three blade Roots blower involves multiple aspects, including fault diagnosis, disassembly and inspection, repair and replacement of components, assembly and commissioning, etc. The following is a detailed guide for the maintenance of the Three Leaf Roots blower:

1、 Fault diagnosis

Before repairing the Roots blower, the first step is to perform fault diagnosis on the blower to determine the type and location of the fault. Common faults include excessive noise, unstable operation, high temperature, unstable air pressure, etc. By listening to sound, observing vibration, measuring temperature, and other methods, it is possible to preliminarily determine the location of the fault.

2、 Dismantling and Inspection

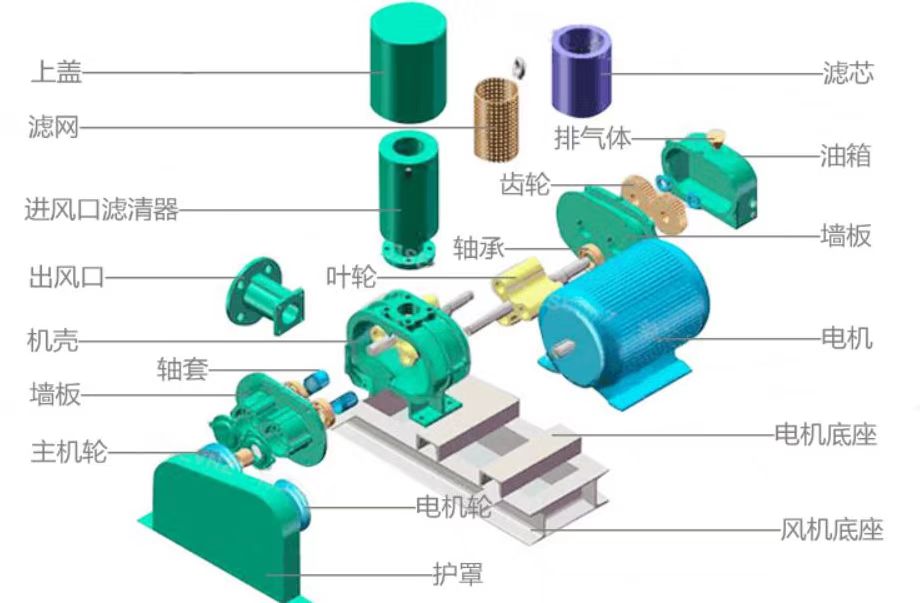

1. Dismantling the fan:

Separate the coupling, remove the foot screws, and lift the fan out.

Remove the coupling and end cover, and sequentially disassemble the gear, bearing, bearing seat, and air seal.

Dismantle the wall panel (when dismantling the wall panel, the fan should be erected) and lift out the rotor.

2. Check the components:

Conduct a detailed inspection of the disassembled components, including impellers, bearings, seals, gears, etc. Check whether the impeller is worn or deformed, whether the bearings are damaged, whether the seals are aged or damaged, whether the gears are worn, etc.

3、 Repair and replacement of components

1. Replace the impeller:

If the impeller is severely worn or deformed, it is necessary to replace it with a new one in a timely manner. Ensure that the model and specifications of the new impeller are consistent with the original impeller.

2. Replace bearings:

If the bearing is damaged, a new bearing needs to be replaced. During the replacement process, attention should be paid to the installation position and clearance adjustment of the bearings.

3. Replace the seal:

If the seal is aging or damaged, it needs to be replaced with a new seal. Ensure that the model and specifications of the new seal are consistent with the original seal and installed correctly.

4. Cleaning and lubrication:

Clean the inside of the fan to remove oil stains and impurities. Lubricate and maintain components such as bearings to extend their service life.

4、 Assembly and Debugging

1. Assemble the fan:

Assemble in the reverse order of disassembly. Ensure the correct assembly position and sequence of each component to avoid deviations.

2. Adjust gap:

Adjust the gaps between impellers, impellers and wall panels, impeller tops and casings, and other components. Ensure that the gap is within the specified range to ensure the normal operation and performance of the fan.

3. Debugging the fan:

After assembly, debug the fan. Observe whether the fan runs smoothly, without any abnormal sounds or vibrations. Check the temperature and sealing condition of each component to ensure that the temperature and sealing condition of each component of the fan meet the requirements under normal operation.

5、 Daily maintenance and upkeep

In order to ensure the long-term stable operation of the Three Leaf Roots blower, daily maintenance and upkeep are also required:

1. Regular cleaning:

Regularly clean the dust and debris inside the fan to maintain its cleanliness.

2. Lubrication and maintenance:

Regularly lubricate and maintain bearings and other easily worn components to extend their service life.

3. Check for wear and tear:

Regularly check the wear of the fan impeller and other components, and replace severely worn parts in a timely manner.

4. Operating standards:

When operating the Roots blower, follow the operating procedures and requirements. Avoid overloading and overspeed operation to ensure that the fan operates in a suitable environment.

In summary, the steps and precautions to be followed when repairing a three blade Roots blower. By correct fault diagnosis, disassembly and inspection, repair and replacement of components, assembly and commissioning, as well as daily maintenance and upkeep measures, the normal operation and extended service life of the fan can be ensured.