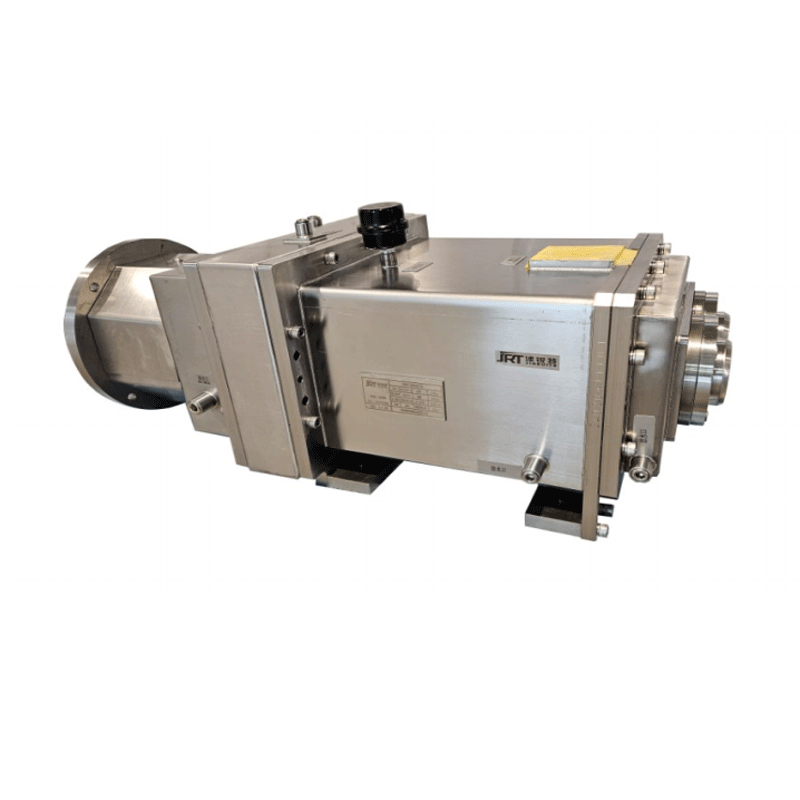

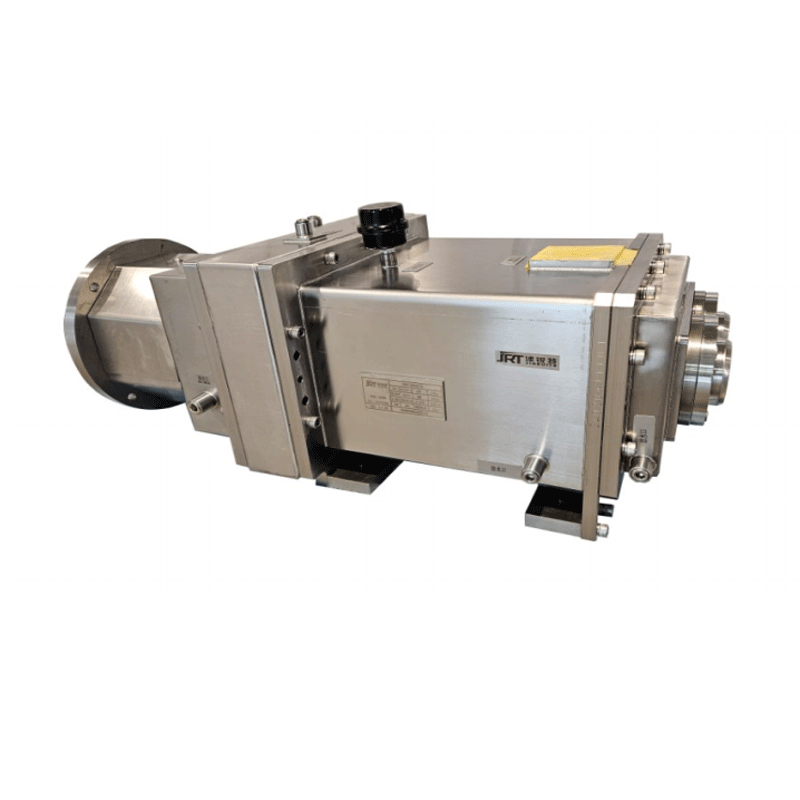

**Detailed explanation of oil-free dry screw vacuum pump**

Oil Free Dry Screw Vacuum Pump is a high-performance vacuum equipment that requires no oil lubrication, no pollution, and corrosion resistance. It is widely used in industrial fields with strict cleanliness requirements. Its core feature is the use of precision meshing screw rotors to achieve gas suction, compression, and discharge in an oil-free environment.

---

**1、 Core working principle**

**1. Structural composition**

-Twin screw rotor (usually made of stainless steel or coated material):

-The main and secondary rotors rotate synchronously in reverse through high-precision gears, maintaining non-contact meshing (clearance of 0.1~0.3 mm).

-Common rotor profiles: * * asymmetric type, spiral twisted blade type * * (to reduce airflow pulsation).

-Pump casing (stainless steel/cast iron+anti-corrosion coating):

-Corrosion resistant design, suitable for acidic and alkaline gas environments.

-Cooling system (water-cooled/air-cooled):

-Control compression heat to prevent rotor deformation.

-Sealing system (dual mechanical seal/magnetic coupling):

-Ensure zero leakage, suitable for toxic or flammable gases.

**2. Working process**

1. * * Inhalation stage * *: Gas enters the closed chamber formed by the rotor and pump casing from the intake port.

2. * * Compression stage * *: The rotation of the rotor gradually reduces the volume of the chamber, and the gas is pushed axially and compressed.

3. * * Exhaust stage * *: Compressed gas is discharged from the exhaust port without oil involvement throughout the entire process.

---

**2、 Core advantages**

|* * Features * * | * * Advantages * *|

|---------------------|-------------------------------------------------------------------------|

|* * Oil free * * | Oil free steam pollution, suitable for clean industries such as medicine, food, electronics, etc|

|Strong corrosion resistance * * | Stainless steel (304/316L) or coated rotor, capable of handling corrosive gases such as Cl and HS|

|* * Wide pressure range * * | Single stage ultimate vacuum:** 0.1~10 Pa * *, multi-stage series can reach 0.01 Pa * *|

|* * Low maintenance cost * * | No need for lubricant replacement, only regular cleaning of the rotor/filter is required|

|* * Energy saving * * | Compared to oil sealed rotary vane pumps, it saves 30-50% energy and is more compact than Roots pumps and front-end pump systems|

---

**3、 Typical application areas**

**1. Semiconductor and Electronics Industry**

-Wafer manufacturing: PVD/CVD coating (maximum vacuum ≤ 0.1 Pa).

-LED packaging: Vacuum defoaming (10-50 Pa).

-Electron beam welding: prevents metal oxidation (0.01~1 Pa).

**2. Pharmaceutical and Bioengineering**

-Freeze drying machine (freeze-drying drugs, vaccines): Maintain a vacuum environment of 1-10 Pa.

-Aseptic filling: Vacuum filling with nitrogen (10-100 Pa).

**3. Chemical and Energy**

-Solvent recovery: VOCs are recovered at -0.08~-0.095 MPa.

-Drying of lithium batteries: dehydration of electrode plates (0.1~1 kPa).

**4. Food industry**

-Vacuum packaging: residual oxygen content<1 (-0.09~-0.1 MPa).

-Freeze drying: Dehydration of fruits and vegetables (10-50 Pa).

---

**4、 Key performance parameters**

|* * Parameters * * | * * Typical Range * * | * * Remarks * *|

|-------------------|---------------------------|---------------------------------------|

|Extreme vacuum | 0.1~10 Pa (single-stage) | Multi stage series can reach 0.01 Pa|

|Extraction rate | 5-2000 m3/h | positively correlated with rotor diameter/speed|

|Working pressure range | Atmospheric pressure~0.1 Pa | Suitable for rough vacuum to medium high vacuum|

|Motor power | 1.5~355 kW | depends on flow rate and compression ratio|

|Temperature resistance | -20 ℃~150 ℃ (standard) | High temperature type can reach 300 ℃ (special coating)|

---

**5、 Key selection points**

1. * * Gas properties * *:

-Corrosive gases require the selection of 316L stainless steel or coated rotors.

-Dust containing gases require the installation of a pre filter (accuracy ≤ 1 μ m).

2. * * Vacuum requirement * *:

-Single stage pump is suitable for 1-1000 Pa, high vacuum requires Roots pump/molecular pump.

3. * * Cooling method * *:

-Water cooling: suitable for high-power or high-temperature conditions (>75 ℃).

-Air cooling: easy to maintain, suitable for small flow devices.

---

**6、 Maintenance and troubleshooting**

**1. Daily maintenance**

-* * Monthly inspection * *:

-Rotor clearance (wear>0.05 mm needs to be adjusted).

-Filter blockage (replace when pressure difference>5 kPa).

-* * Annual maintenance * *:

-Replace the bearing (with a lifespan of approximately 20000 hours).

-Check the synchronization accuracy of the gear (replace if the backlash is greater than 0.2 mm).

**2. Common troubleshooting**

|* * Fault phenomenon * * | * * Possible cause * * | * * Solution * *|

|------------------|-------------------------|----------------------------------|

|Vacuum degree decrease | rotor wear/system leakage | helium leak detection+replacement of seals|

|Abnormal vibration | Bearing damage/dynamic balance failure | Bearing replacement+rotor dynamic balance correction|

|Overheating (>90 ℃) | Insufficient cooling/high compression ratio | Clean the cooling channel+check the exhaust back pressure|

---

**7、 Comparison with competitors**

|* * Comparison item * * | * * Oil free screw pump * * | * * Oil sealed rotary vane pump * * | * Roots pump * *|

|------------------|--------------------------|----------------------------|--------------------------|

|Extreme vacuum * * | 0.1~10 Pa | 0.1~1 Pa (but contaminated with oil) | 1~100 Pa (requires a pre pump)|

|* * Cleanliness * * | Oil free | Oil vapor pollution | Oil free but requires lubrication of gears|

|* * Maintenance cost * * | Low (oil-free) | High (regular oil change) | Medium (gear/bearing maintenance)|

|* * Price * * | High (30~50 expensive) | Low | Medium|

---

**Summary**

Oil free dry screw vacuum pump is a highly clean, corrosion-resistant, and low maintenance vacuum solution, especially suitable for industries such as semiconductors, pharmaceuticals, and food that have zero tolerance for oil pollution. When selecting, special attention should be paid to gas composition, vacuum requirements, and cooling methods, and the rotor and sealing system should be regularly maintained to extend their lifespan.